|Feature|Lineup|Data Sheet|Development Flow|

A thermoplastic elastomer designed for vibration damping and shock absorbing.

Feature

- Ultra low durometer JIS TYPE A0~

- No LMW siloxane and sulfur used that could cause contact failure

- No restricted substances materials used (RoHS compliance)

- No halogen compound used (CI, Br, Red phosphorus and Sb)

- Available in UL rating grade

- Injection moldable material

- Sheet or 3D molded geometry available

- Recyclable material

- Can be molded with other materials(double shot and insert molding) => excellent choice for hard resin double shot molding for composite molding products.

| double Shot Molding | Insert Molding |

|

|

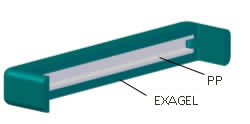

| EXAGEL is moldable by double shot molding process with polyolefin (non-polar resin like PP) |

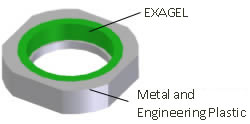

Insert molding is available by applying a primer beforehand. |

Lineup

|

A thermoplastic elastomer has excellent moldability and very low durometer. |

|

Enhanced high attenuation properties on the general purpose grade. It has small impact resilience and excellent vibration and shocking absorption performance. |

|

. |

Data Sheet

| Specifications | unit | General Purpose Grade | High Attenuation Grade | UL V-0 Rating & High Attenuation Grade | |||||

|---|---|---|---|---|---|---|---|---|---|

| FES- 10114 |

FES-

10136-G84 |

FES- 14530-B81 |

FES- 14450-B81 |

FES- 15020 |

FES- 15050 |

FES- 15070 |

FES- 15080 |

||

| Color | ー | Black* | Gray* | Black* | Black* | Black | Black | Black | Black |

| Hardness | type A | A4/E23 | A14/A13 | A28/A24 | A51/A46 | A19/A13 | A53/A44 | A69/A59 | A80/ー |

| (Momentary /After 15sec) |

(Momentary Value Only) |

(Momentary Value Only) |

|||||||

| Tensile Strength | MPa | 1.1 | 1.7 | 2.3 | 4.9 | 0.6 | 1.9 | 3.1 | 5.8 |

| Elongation | % | 490 | 580 | 630 | 430 | 250 | 240 | 220 | 590 |

| M100 | MPa | 0.4 | 0.7 | 1.2 | 2.5 | 0.5 | 1.7 | 2.8 | ー |

| Tear Strength | N/mm | 5.8 | 9.3 | 15.6 | 22.1 | 5.2 | 13.4 | 17.3 | 24 |

| Compression Set | % | 17 | 40 | 89 | 75 | 43 | 24 | 18 | 40 |

| 70℃24h | |||||||||

| Loss Factor | (23℃/30Hz) | 0.15 | 0.12 | 0.55 | 1.12 | 0.42 | 0.55 | 0.46 | 0.2 |

| tanδ | |||||||||

| Flame Retardance | UL94 | HB | HB | HB | HB | V-0 | V-0 | V-0 | V-0 |

There are other grades available other than listed grades. Please feel free to contact us for further details.

*Available in customizing colors

Development Flow

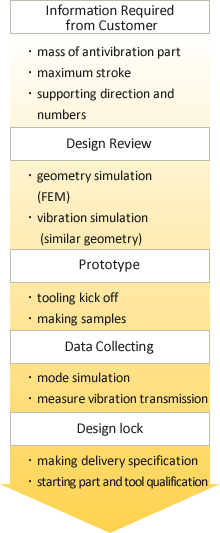

Upon receipt of your design information, we suggest the most optimized damper design by following the development flow. Contact Polymatech today for your complete application solutions.

|

Using the finite element method, we estimate design limitation comes a setting space availability, stress concentration at stroke and constant of spring. |