|Specific Characteristics|Example of coating with heat release grease|

Conventional thermal conductive sheets, thermal conductive greases can

be applied in a much thinner layer and offer extremely low thermal resistance.

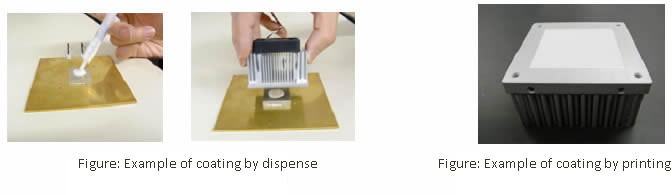

The outstanding handling properties make for ease of grease Dispensing and coating

onto substrates.

In addition, the use of non-silicone base oils eliminates problems such as contact

faults caused by low-molecular siloxane.

Specific Characteristics

| Specifications | Unit/Grade | GA200 | GA204 | GA401 | GA690 |

| Thermal Conductivity* 1 | W/(m・K) | 2 | 2.4 | 4.1 | 4.5 |

| Appearabce | ー | White | White | Gray | Gray |

| Base Material | ー | Ester oil | Ester oil | Ester oil | Ester oil |

| Viscosity | Pa・s | 170 | 110 | 350 | 300 |

| Specific Gravity | ー | 3.1 | 3.2 | 2.55 | 2.55 |

| Minimum Thickness | μm | 20 | 20 | 25 | 25 |

| Solvent Inside? | ー | No | No | No | Yes |

| Operating Temperature | ℃ | -40 ~ 150 | -40 ~ 150 | -40 ~ 150 | -40 ~ 150 |

| Package Type | ー | Can or Syringe | Can or Syringe | Can or Syringe | Can |

* 1 Hot Wire Method.

Example of coating with heat release grease